+86-577-62705111

info@sc-connector.com

CONTACT US

ENGLISH

As the name implies, cable waterproof connectors can be applied to environments with water to provide safe and reliable connector joints, the most important of which is the ability to achieve waterproof effects. So how to select the type of waterproof cable connector?

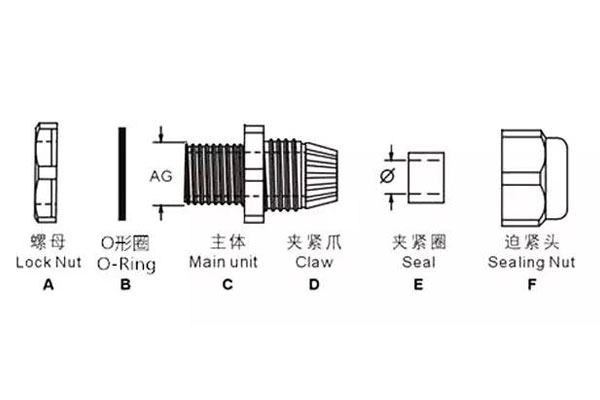

The main body, nut and pressing head of the plastic waterproof joint are made of nylon PA66; the nylon pipe fittings are green and environmentally friendly, non-toxic to the human body, no secondary pollution and suitable for long-term contact with water, no corrosion, no toxicity, and no rust. The static working temperature is suitable for -40℃~100℃, the instantaneous heat resistance can reach 120℃, the dynamic working temperature is -20℃~80℃, the instantaneous heat resistance is 100℃. Special clamping jaws and rubber parts design, wide clamping cable range, strong tensile strength, cable gland waterproof, dustproof, saltproof, acid and alkali resistant, alcohol, grease and general lubricant.

The metal waterproof cable gland is nickel-plated brass, the clamping claw is nylon material, and the clamping ring uses soft NBR to fasten the cable, so that the cable does not leave marks after the connector is removed; it has good high temperature resistance, corrosion resistance, and high pressure resistance Performance, salt spray test is not less than 200 hours.

Installation and use scope:

Generally, one end of the thread is fixed on the shell, and the nut is tightened in the shell to fix it (or according to the selection of thread access to the electric equipment whose internal thread is imported and exported), the cable is directly led out from the waterproof connector, and the nut is tightened properly, so that The cable can be protected.

It is widely used in the fixing and protection of wire and cable in mechanical equipment, electrical, marine electrical and anti-corrosion equipment.

main effect

Fastening and sealing of cables. Tightening refers to locking the cable through a waterproof connector so that the cable does not have axial displacement and radial rotation, ensuring that the cable connection is normal. Sealing means isolating water and dust from entering.

1. Determine the IP protection level that the cable gland needs to achieve according to the usage environment and requirements of the cable connector;

2. Determine the material and color of the cable gland according to the usage environment and requirements of the cable connector;

3. Determine the thread specifications and thread standards required for the cable gland;

(Thread standard description: EN60423 metric thread M; DIN40430 German thread PG)

4. Choose a cable model that is close to the outer diameter of the cable, and the bayonet range of about +10% is used as the specific model;

5. Under normal circumstances, it is recommended to use O-rings to achieve the IP67 technical standard;

6. According to the thickness of the machine board, whether it is necessary to lengthen the thread;

7. If it is used in an explosive or flammable gas occasion, an explosion-proof joint is required;

8. If there are electromagnetic compatibility requirements, you need to choose EMC shielded connectors;

9. Check the specifications, please contact SAICHUANG for any question.

1. Use different materials for cable waterproof glands in different environments;

2. It is recommended to use a torque wrench to tighten (recommended);

3. When the requirements above IP65 are required, O-rings must be used;

4. In order to ensure a certain pressure at the joint, it is recommended to add a sheath tube to strengthen the insulation and protection;

5. In order to ensure waterproof and longer-term operation, it is recommended to use double-wall glued heat shrinkable sleeves and insulating sleeves for reinforcement;

6. During construction, it is best to adopt a staggered butt joint method (that is, the cable does not need to be neatly cut and docked);

7. The self-adhesive tapes (or heat-shrinkable waterproof tapes) used are high-voltage products to ensure insulation safety.